The TLS Anilox GmbH, based in Salzkotten, manufactures coated and laser engraved anilox rolls and sleeves for the printing and coating industry. We are now launching a new product – TeroLux – with a nearly non-porous surface resulting in amazing printing results.

For more than three decades, the ceramic coating of anilox rolls has proven its worth / has stood to the test. These laser engravable coatings provide an extremely high wear protection. Nevertheless, the R&D department at TLS Anilox GmbH has been exploring further potentials for optimization. During this development process, we were able to resolve the remaining porosity of the ceramic coating and advance to the unlimited field of finest lines. The result: TeroLux.

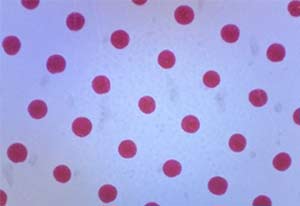

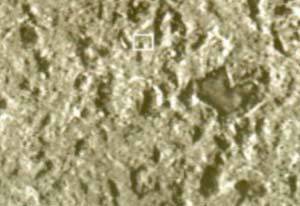

TeroLux 340 L/cm, 5.4 cm³/m²

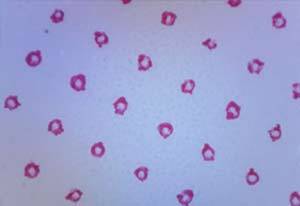

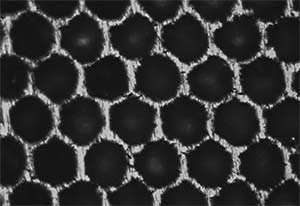

Keramik 340 L/cm, 5.4 cm³/m²

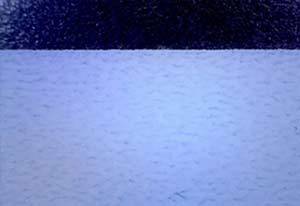

Form / characteristic in the marginal region

Photo of TeroLux engraving

Currently, inquiries about high-quality print motives in flexible packaging having been increasing, subsequently putting higher demands on greater screen counts on printing plates, and on anilox rolls. The metallic surface allows a detailed reproduction of very fine screen dots with a high edge definition resulting in prints of an outstanding quality.

Existing lines can be replaced by finer engravings without having to put up with a loss in density or having to change the ink management. In addition, the closed and smooth gutters of the engraving provide a good support to the screen dot. Although nearly identical values regarding opacity were obtained during the test, significantly sharper edges can be printed with the finer engraving.

TeroLux (grinded)

Chromium oxide (grinded)

Advantages of TeroLux

- Long service life

- Easy to clean

- Ideal for fine lineatures

- Reduction of the wear on the Doctor blade

- Low-vibration operation

- Homogeneity

Conclusion

The print tests with TeroLux rolls yielded very impressive results. It also became obvious that this new coating material holds a great number of potentials yet to be explored. This suggests that in the future engraving parameters can be implemented which today fail at physical constraints.

Author: Jürgen Brauckmann